| Surveying | |

Locating dangerous zones prior to drilling the 57 km long Gotthard Tunnel in Switzerland

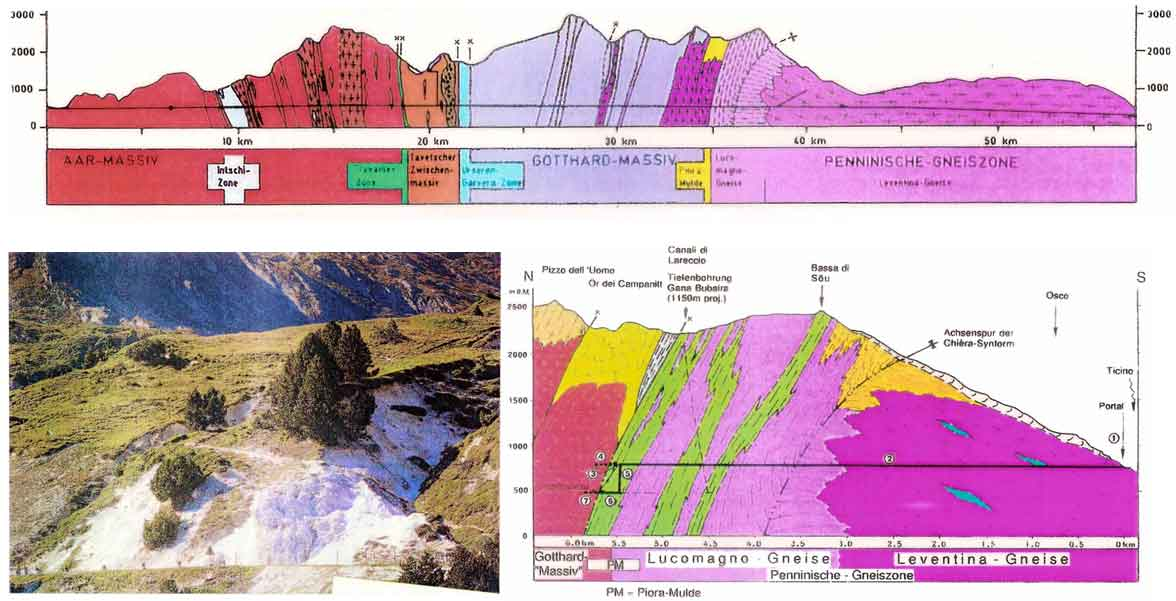

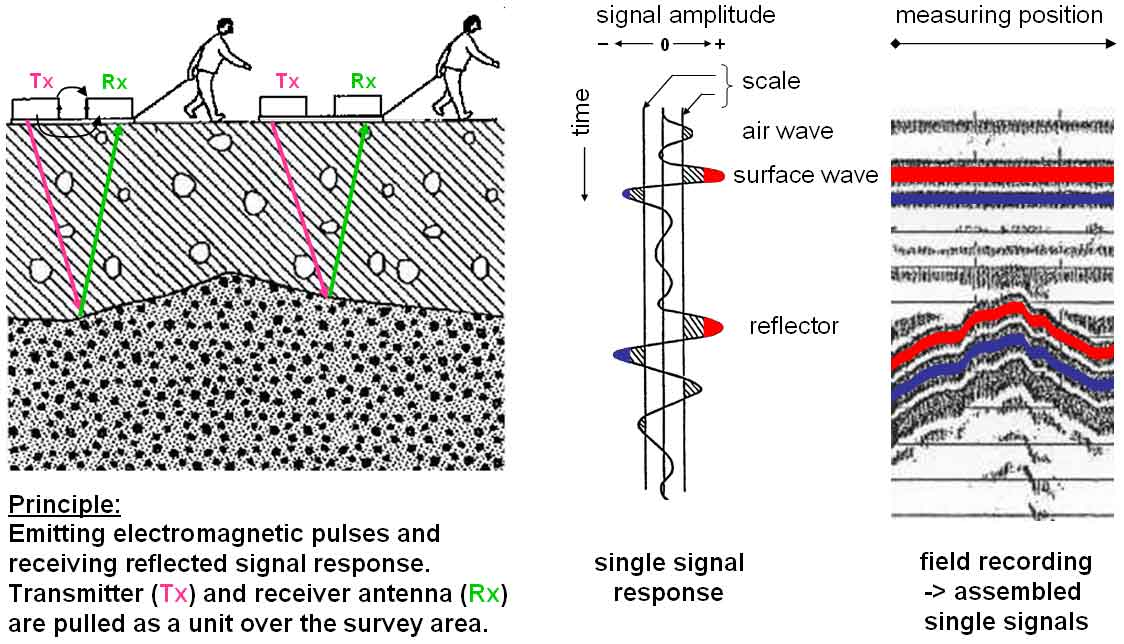

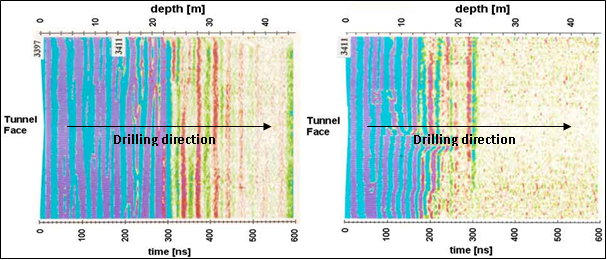

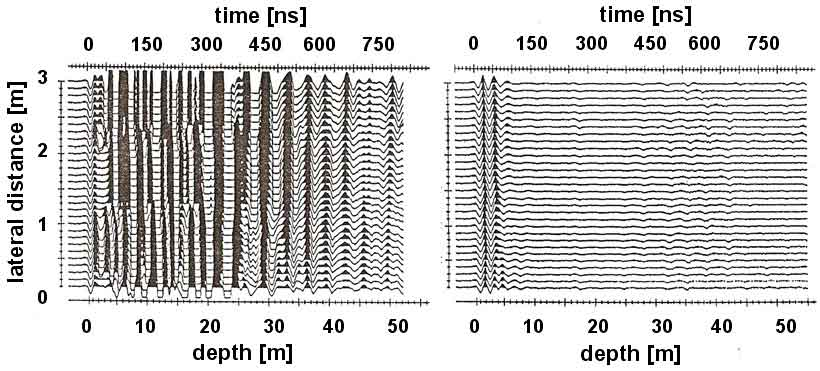

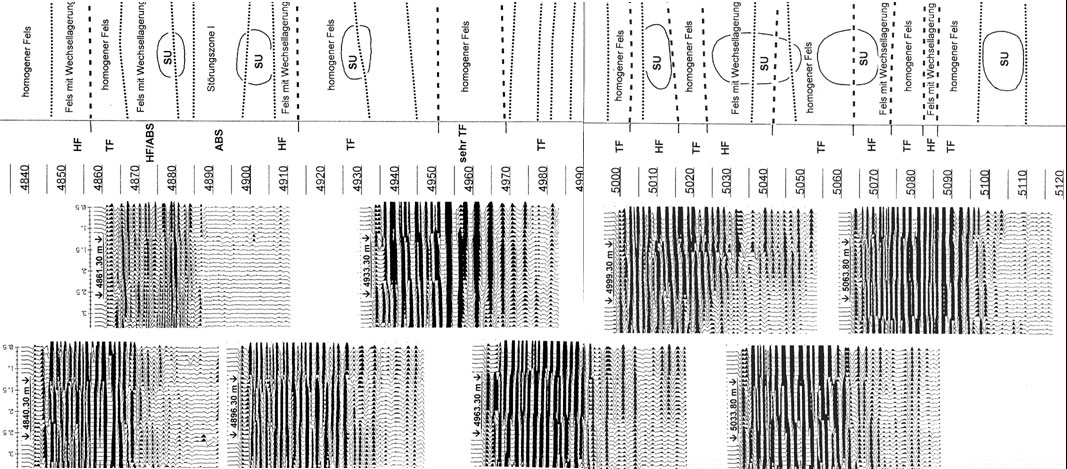

The Gotthard Base Tunnel with its 57 km is the world’s longest railway tunnel (Figure 1). It is located beneath the Swiss Alps and consists of two single track tunnels, several cross-cuts and shafts with a total length of 153.5 km. The constructions started in 1996. The eastern tunnel was completed on 15 October 2010 and celebrated with a cut-through ceremony (Figure 2). The constructions are planned to end by 2016 and the opening to the traffi c by 2017 [1]. The tunnel leads through largely disturbed granite and gneiss massifs interrupted by weak and instable rock formations (Figure 3, top). The maximum overburden is up to 2500 m, the hydrological situations are highly variable. The most dreaded geological formation was the so-called “Piora Mulde” (Figure 3, yellow marked). The material of this formation has the consistancy of sugar and is therefore called sugar grained dolomite. It has no mechanical stability at all. At the beginning in 1995 nobody knew whether this formation would reach down to the planned tunnel level. In order to gain more detailed information a sounding tunnel was built prior to the construction of the base tunnels.The sounding tunnel was built 300 m above the planned base tunnel [2]. Georadar principleGPR is a geophysical investigation method. Its principle is similar to that of Seismics but instead of emitting elastic waves, it emits electromagnetic waves. They are much shorter, which leads to a much higher spatial resolution. GPR is sensitive to the electromagnetic properties of the material under investigation. Interfaces of rock formations, fi ssures and aquiferous areas are displayed. The System consists of a transmitter antenna, a receiver antenna and a control unit. The GPR transmitter antenna produces high-frequency electromagnetic energy pulses. These pulses penetrate the ground and are refl ected at interfaces of media with high contrasts in electrical conductivity. The refl ected waves are captured by the receiver antenna and are displayed continuously on the control unit, producing a so-called radargram (Figure 4). Depending on the required depth of penetration and spatial resolution, different antennas are used: The lower the antenna frequency, the deeper the penetration. Prior to the measurements the antenna confi guration was calculated in order to achieve the necessary depth of penetration. The excavation performance in the hard gneiss was about 14 m per day. The requirement was 20 m penetration depth, which is 1.5 times the excavation performance of the TBM. Whether a target is visible or not depends on the material in the expected fault zone. Calculations of the achievable penetration depth using 100 MHz antennas and a rock model ‘gneiss’ and target ‘water’ resulted in a value of 61 m for a specular and 37 m for a rough target. SurveyFor the required penetration depth only unshielded antennas with frequencies of 100 MHz and 50 MHz could be used. We choosed the “pulseEKKO” system built by the canadian company Sensors&Software Inc. That Georadar equipment was small enough to fi t through the narrow manhole of the TBM to get to the drilling face (Figure 5). Prior to the measurement the TBM was pulled back 1.5 m at a time. Then the fi rst man crawled through the several meters long manhole, while the second man pushed the equipment through the manhole and prepared the Figure 6: GPR 100 MHz antennas (top left), Manhole with fi bre optics (top right), engineers passing GPR equipment through a manhole (bottom left) and carrying protection tubes for the vulnerable fi bre optics (bottom right). Photos: E Meier, U. Sambeth. The profiles always run from left to right. The centre of the profi le coincides with the centre of the bore hole. The measurement in front of the TBM could be performed by two people in a few minutes. It could be combined with the check of the rotary bits. First, two test measurements were carried out at tunnel meters 3397 and 3411. After satisfying results, a second fi eld campaign was conducted from tunnel meter 4840 to 5120 (Figure 7, 8). ResultsUnlike a normal GPR measurement the display of the radar signals in the radargrams is forward oriented, towards the progress of drilling. Figure 7 displays a colour image of a radar section at tunnel position 3397 m and one at position 3411 m. At 24 m distance in the record at the left side a fault zone is clearly visible. In the fi gure on the right side this fault zone has approached, it is now at a distance of only 14 m from the drilling face. The evaluation of the events is based on the radargram interpretation and the geological outcrop [4]. Figure 8 demonstrates different georadar images of different rock qualities. Images like the one on the left represent a high quality rock. In critical zones where water intrusions were present, already after a few meters no reflectors were visible any more (Figure 8, right). An overview of overlapping georadar profiles is shown in Figure 9. At position 4875 a small fault zone was detected. The georadar image of that zone shows a clear signal absorption halfway in drilling direction. This was verified by the geological outcrop. The last Georadar record was taken on 28 November 1995. On 31 March 1996, between 12:30 and 17:00, during the pilot hole drilling from position 5553 into the critical zone, an operating error ocurred and the tunnel was fi lled with 2000 tons of water and sugar grained dolomite [5]. Fig. 7: Coloured profiles of the two test measurements at tunnel meter 3397 m (left) and 3411 m (right). In the first record the blue range (reflections with big amplitudes) is reaching 24 m deep, in the second record 14 m deep. Fig. 8: 50 MHz Georadaprofiles representing high quality solid rocks (left) and rock at a fault zone (right).

Fig. 9: Overview of overlapping series of georadar profiles recorded between position 4840 m and 5120 m Figure 10: Blow-out from borehole at 5553 m. A mixture of sugar grained dolomite and water with 1000 m overpressure filled the tunnel. Photo R.Volpers [6] ConclusionGeoradar is a feasible tool for detecting dangerous waterfi lled zones in granitic rocks. It is a very quick methode and can be carried out during the check of the drilling bits. Pilot holes are still necessary for safety reasons. However, the number of pilot holes can be reduced and limited to the critical zones, which also reduces the costs considerably. References[1] Unterschütz, P., 2005, The New Gotthard Rail Link, AlpTransit Gotthard Ltd., Lucerne The paper was presented at FIG Working Week 2011, Marrakech, Morocco, 18-22 May 2011

|

(3 votes, average: 1.33 out of 5)

(3 votes, average: 1.33 out of 5)

Leave your response!