| Surveying | |

Mine surveying in Finland – Education and professional practices

The standardization of mine surveys, and education related to control surveys, have to be developed in the coming years |

|

|

Finland is a European hub for mineral exploration and mine development. Nickel, zinc, copper, chrome and gold form Finland’s most significant metal mineral resources. Metal, industrial mineral, and rock mines can be found all over Finland. Especially Lapland, which is located in Northern Finland, and Eastern Finland are important mining areas. Mines in Lapland are the biggest producers of cobalt, platinum, palladium and gold in European Community. Land surveyors are important for mining industry. It is land surveyors’ benefit that land surveying is a multidisciplinary science, which has three strong sides, namely measurement science, land management and spatial information management. Mine surveyors are land surveyors who work in demanding working conditions in open-pit and underground mines. They are capable to use highly sophisticated surveying techniques to produce accurately, quickly and efficiently various 2D and 3D representations of the real mining world in purpose to assist various mining operations. In every mine you can find a mine surveyor, or even more. Mine surveyors are especially responsible for maintaining an accurate plan of the mine as a whole. Quite often they are for more than that. Well educated and practiced they can be involved in every aspect of a mining operation. This includes land use planning, legal issues, initial exploration, initial construction of mine operations, ongoing mining works, and rehabilitation of mine site after mining is completed. Mine surveyor can be seen as a kind of manager of the resources of a mine. Accurate surveying starts from control points, which define coordinate and height reference frames. Quite often mine reference frames are local systems. Anyway, coordinate transformations between local and national frames has to be defined, because the national authorities use documents and GIS data sets in the national frame. Control surveys can be seen as a weak point of the present professional practices in Finnish mines. Control surveys, and education related to them, has to be developed in the coming years.

The Finnish minerals sector

Finland is nowadays a European hub for mineral exploration and mine development. With right geology, long mining history and excellent geological data basis, Finland is perfect place to mine and invest in mining. Metal, industrial mineral and rock mines can be found all over Finland, but especially Northern and Eastern Finland are important mining areas. Mines in Lapland, in Northern Finland, are the biggest producers of cobalt, platinum, palladium, and gold in European Community, and the Agnico Eagle Kittilä mine is the largest gold mine in Europe. It extracts annually 1.6 million tons of ore, yielding about 6000 kg of gold (Agnico Eagle 2018a). Also new mines are mostly situated in Lapland and Eastern Finland, supporting the development of these regions. Currently there are three active mines and six mine development projects in Lapland. It is expected that at least five of the development projects will lead to the construction of new mines (Mining Finland 2018).

The minerals sector covers a diverse range of activities, including the mining of metallic ores and industrial minerals, as well as other industries that extract and process aggregates and natural stones. The minerals sector is also considered to include industries that produce and supply machinery, equipment, technology and services for mining operations. In addition the minerals sector is supported by various institutions including research organizations, universities and vocational schools. Mineral resources represent a significant part of the Finnish national wealth. Nickel, zinc, copper, chrome, and gold form Finland’s most significant metal mineral resources. The vision for 2050 is that Finland is a global leader in the sustainable utilization of mineral resources and the minerals sector is one of the key foundations of the national economy (The Ministry of Employment and the Economy 2010).

Mining activities fall under the jurisdiction of the Finnish Mining Act, and the Environmental Protection Act, with respect to assessment of environmental impacts. The acts are aimed to promote mining operations and organize the land use, including exploration preceding the mining operations, in a socially, economically and ecologically sustainable manner, with due account for both public and private interests. (Mining Act 621/2011.)

The role of land surveying in the minerals sector

Land surveyor

Ordinary people think quite simply that land surveying is the technique, profession, and science of determining the terrestrial position of points and the distances and angles between them. These position of points and measurements are further understand to be used to establish various maps, property boundaries, and other purposes required by clients and authorities. A more professional approach to land surveying is to see it as a multidisciplinary science, which has three strong sides, namely measurement science, land management, and spatial information management (Enemark 2007). Measurement science refers to surveying and mapping. They are clearly technical disciplines within natural and technical science. Land management refers to cadastral surveying and land use planning, which are judicial and managerial disciplines within social science. Spatial information management refers to GIS, or geographic information system. GIS is a kind of link between measurement science and land management. The strength of land surveying profession lies in this multidisciplinary approach. This is also true with land surveyors who work in the minerals sector.

Land surveyor as mine surveyor

In Finland, land surveyors are involved in many ways in mining operations. These include land use planning, legal issues, initial exploration, initial construction of mine operations, ongoing mining works, and rehabilitation of site after mining is completed. Land surveyors work in public organizations and private companies, which operate in the minerals sector, or which have links to it. Not all of these land surveyors are strictly speaking mine surveyors, but they have certain tasks related to mining.

Mine surveying is a special field of land surveying. Mine surveyors are land surveyors who work in open-pit and underground mines. They are especially responsible for maintaining an accurate plan of the mine as a whole. Quite often they are for more than that. Because land surveying is a multidisciplinary science, educated and practiced mine surveyors are capable to work in many tasks related to mining operations.

Mine surveyor’s work starts from the discovery and delineation of mineable ore deposits. After feasibility and economical assessments follows the actual mining activities. They comprise exploration, surveying, construction, drilling, blasting, scaling and reinforcement, dewatering, loading and haulage, and ore enrichment.

Mine surveyors are responsible for maintaining an accurate plan of the mine as a whole. Accurate surveying is based on reliable control points. The maintenance of control network is a very basic task of mine surveyors. Based on the control points, mine surveyors update maps of the surface layout to account for new buildings, other structures, and utilities, as well as they survey the openpit and underground mine workings in order to keep record of the mining.

Mine surveyors help find precious and nonprecious metals and minerals by measuring mines, tunnels and other underground or surface works. Mine surveyors are involved in the measuring process to calculate ore production, in volume or mass units. In addition to this, the volume of the dumps of waste accumulating on the surface of the mining property will also be surveyed. This aspect of the work has turned the mine surveyor into a kind of manager of the resources of the mine (Laurila 2015).

Since valuable minerals occur in a variety of concentrations in the ore, the mine surveyors, in cooperation with the geologists and geophysicists, are responsible for dividing up the ore body into blocks where the average grades of the ore are known. This allows the mine engineers to decide which blocks are economical to extract and which are not. As a result of this information a plan for the extraction of a blended mixture of low and high grade ores can be made. This kind of planning ensures that the mining process is prolonged, the removal of ore is optimized and the metallurgical processing plants, which will not work well if there are large grade variations, are able to operate at consistently high levels of efficiency.

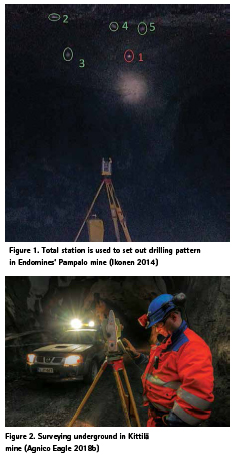

Usually blasting is required prior to excavation. The process involves the use of drilling machines to drill a pattern of bore holes, which are then loaded with explosives and detonated. Mine surveyors are involved in the process by setting out pegs or other marks for an area to be prepared for drilling, marks for drill operators to know where to drill, as well as surveying the material once it has been blasted (figure 1). In open-pit mines, machine guidance systems may be in use. Then drilling machines have GNSS receivers attached and they are able to drill a pattern without the use of pegs. Mine surveyors are responsible operators of these machine guidance systems.

Safety is a big issue in any mine. Surveying and mine mapping has a direct effect on the safety of people working in the mines. Mine surveyors play important role by accurately locating potential hazards, for example flooded tunnels. If an accident occurs, surveying operations must be performed immediately to aid in rescue efforts. Time is important, and confidence in the surveying and mapping system of the mine is essential.

The lifespan of a mine is long, usually decades. After its active time, the mine is closed. Then the plans prepared by mine surveyors become important historical documents. They are possibly used for future mining of the site, if new reasons to open the mine occurs, or rehabilitation and environmental planning of the site, if it is finally closed.

General competencies for mine surveyors

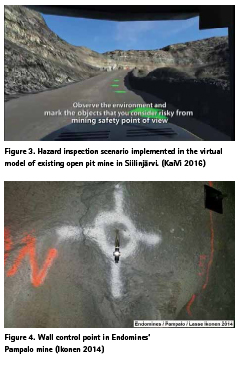

Mine surveyors use quite conventional surveying practices, but their working environment is very different from other land surveying (figure 2). It is more demanding to work in busy mine than under peaceful open sky. Mine is a constantly changing working environment. A place that was safety previously can be dangerous next time. Air humidity, dust and gases, even dangerous gases like carbon monoxide (CO), create problems for workers, instruments and machines. Traffic is also a major challenge in mines. Mine surveyors have to be creative with traffic related problems when they plan and perform their measurements. (Alatalo 2017.)

In Finland, mine surveyors usually work alone, so they should be self-reliant and their problem-solving skills should be at good level. Mine surveyors should be punctual in terms of working times and surveying tasks. They should be self-critical in order to be able to evaluate their work’s meaning for the mining process. The management of the mining process as a whole and the understanding of mining techniques make it much easier to set priorities to their own work and to the use of efficient surveying practices. (Alatalo 2017.)

Mine surveyors requires good knowledge of their measuring instruments and programs. When measuring instruments, computer programs, work instructions or working methods are updated, new properties need to be adopted quickly. Technological development and mining companies’ aspiration for higher productivity through automation of operations will change the mine surveying techniques. The technological development enables more detailed information to be available for mining companies (van Wegen 2018). Although technological advances bring new and more efficient measurement methods, many of the conventional ways of doing mine surveys will remain quite the same as today (Alatalo 2017).

Role of research and education

Research has a key role to provide new information and wider knowledge in the mining sector. The challenges, like lower grade ore, demand new expertise in the processes and totally new methods. With ordinary technologies you may have a pile of rocks, but new technologies can change the situation so that you have ore. Education is needed to spread the knowledge and best practices for mining operations. For educational organizations it is essential to provide skilled labor for the mining sector. The mining sector needs vast range of technical and administrative experts. And mines are demanding places to work. That is why we need to teach students to be multidisciplinary, skilled, safety oriented, and responsible employees. (Huhtaniska 2015.)

Mining specific technical studies are available in University of Oulu, Lapland University of Applied Sciences, Kajaani University of Applied Sciences and in three vocational schools, which are all located in Northern Finland. Oulu University offers a degree program in mining and enrichment technology on bachelor and master levels. Lapland and Kajaani universities of applied sciences offer shared studies on bachelor level. The studies have been planned in cooperation with mining companies. The study courses are related to mining technology in general, enrichment technology, maintenance, and mine planning and construction. The vocational schools train miners for drilling, blasting, loading and haulage, and maintenance. All here mentioned degree programs are quite new programs. They have the common problem that the number of applicants for these studies is quite low. Unfortunately this a common problem for all engineering programs in Finland, and worldwide.

In Finland, there are no mining specific studies for land surveyors. Presently most mine surveyors are land surveyors, who have graduated in Lapland University of Applied Sciences. They have reached their specialization trough practical training, and partly through their thesis studies. Generally, mining specific studies are not prerequisite to work in the minerals sector. Most engineers and technical experts for mine companies come from other fields of engineering.

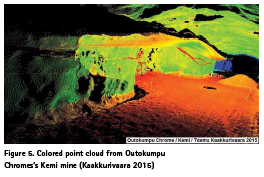

Lapland and Kajaani universities of applied sciences have worked together to develop engineer education in the mining sector for many years. The cooperation has confirmed their role as key providers of engineer education on bachelor level in Eastern and Northern Finland. There have been several development projects. One of the projects has been a virtual learning environment for mining (KaiVi). It is a simulation based, game-like learning environment. It allows for the visualization of the activities and decisionmaking with cause-effect relationships in mines that are difficult or impossible to do without a virtual environment. The training environment can be utilized in various fields of education, such as infrastructure, maintenance, mechanical engineering, construction engineering, electrical engineering, and automation. The students will learn to work together in a multidisciplinary mining environment. This will improve their readiness to work in mines safely. (Figure 3.)

Professional practices in mine surveying

Control surveys

Accurate surveying depends on reliable control points. They define a coordinate reference frame, or a vertical reference frame, or a combined 3D coordinate reference frame. The coordinates and elevations of the control points are measured with special control survey methods. The purpose of control surveys is to provide a uniform framework of reference for the surveying activities within a given area. Triangulation and traversing are used to define the coordinates of control points. Especially traversing is common method in the narrow underground tunnels. Total stations and GNSS receivers are used to make the necessary measurements for coordinates. For vertical reference system, levelling is still the most accurate method to define elevations of vertical control points.

Baseline is the simplest way to establish the coordinate reference frame. Minimum of two control points define the baseline and the principal reference frame. Mine baseline is usually oriented in the direction of the ore deposit. It is often taken as the X-axis of the local rectangular coordinate system. The reference frame is easily extended from the baseline by traversing or by triangulation with total station.

In general, reference frames can be local, national, continental, or global systems. Quite often mine reference frames are local systems. Anyway, coordinate transformations between local and national system has to be defined, because the national authorities use documents and GIS data sets in the national frames. (Mining Act 621/2011 and Government Decree on Mining Activities 391/2012.)

For example, in Kittilä mine, the control network is extensive. There is a sparse primary control network on the ground, which dates back to 1980’s. The primary points defines the reference frame to be the old Finnish national frame, which is not used anymore. The control network continues from the ground through the entrance tunnel and advances along the tunnels to everywhere in then mine, so that there are about 1500 secondary points located on the walls of the tunnels at about 100 m intervals (figure 4). In addition there are approximately the same number of auxiliary points for short term use. Because of the tunnel network expands and mining operations and traffic destroys control points, mine surveyors have to do control surveys continuously. (Alatalo 2017.)

In many Finnish mines, control surveys can be seen as a week point of the present surveying practices. First, problem is that there are no survey standards for control surveys in mines. Second, in many mines the reference frame has been defined long ago without clear documentation. It is possible that the primary points have been destroyed. Third, the mining companies don’t necessarily understand the importance of reliable control frame for their operations and safety. Fourth, the mine surveyors are not always familiar with control surveys. It is quite obvious that standardization of mine surveys, and education related to control surveys, have to be developed in the coming years.

Total stations

Mine surveyors use various surveying techniques and instruments including total stations, terrestrial laser scanners, satellite positioning, and aerial surveying methods, to make their measurements of surface and underground works. Modern surveying instruments are electro-optical and digital devices, which are controlled by computers and connected to the Internet.

Total stations, or tachymeters, are common surveying instruments used today. In Finland, especially in underground mines total station is the most important surveying instrument. Robotic total stations are available which allow for a single-person operation by controlling the instrument using a remote control. Robotic total stations are also capable to scan the objects, but they are much slower scanners than the special terrestrial laser scanners are. In general, robotics allow for automation of measurements. Robotic total stations make it possible that in Finland mine surveyors usually work alone.

Total stations are used with a prism which reflects light signals back to the measurement device to determine a distance measurement. Most total stations can also be used in reflectorless mode. Then they can obtain a distance measurement to an object without the use of a prism. Reflectorless mode, robotics and automation is important for example in hazardous places where occupational safety is in question.

Total stations are not only used for collecting surveys, but also for setting out designs. Using a total station, surveyor can determine where pegs or other marks need to be placed. Most total stations have setting out features and they can use loaded design information to determine where the marks are located with reference to the control points or the design lines.

Terrestrial laser scanners

A laser scanner combines an electronic distance measuring device and two dimensional orientation measuring device with a scanning mechanism. A terrestrial laser scanner is like a fully automatic total station. The output of laser scanning is often referred to as a point cloud. The term comes from the visualization of the measurements. The points are colored according to the intensity or distance of the return signals and as the result the image appears as a combination of closely spaced dots (figure 5).

The primary capability delivered by laser scanners is to be able to measure very detailed, very accurate 3D-coordinate information across wide areas and to long ranges in relatively short periods of time. It is common for laser scanners to produce hundreds of thousands of measurements in a second. No access to the scene being scanned is required, which is important in inaccessible or hazardous places.

Laser scanners have heavy reliance on software processing to enable the delivery of useful results. The point clouds produced as raw data from laser scanners, while visually impressive, are not immediately applicable as survey deliverables. Generally they require the use of specialized software algorithms and workflows to be fully effective.

Satellite positioning

For most of the people satellite positioning means GPS, or Global Positioning System. Professional users of satellite-based positioning are already used to the abbreviation GNSS, or Global Navigation Satellite System. Satellite positioning is based on accurate time determination. The satellite receiver measures the time difference between the transmitted and the received radio signal. The time difference denotes the signal travel time, which reveals the distance between the satellite and the user antenna. Utilizing distance measurements between the user antenna and four different satellites, the receiver can calculate receiver coordinates in a global 3D reference system, which is known as WGS84. Mine surveyors have to work mostly on centimeter accuracy. This is possible with relative positioning techniques, which employ two or more receivers simultaneously tracking the same satellites. Of the two receivers, one is selected as a reference, or base, which remains stationary at a control point. The coordinates of the other receiver, known as the rover, are unknown. The coordinates are determined relative to the base using measurements recorded simultaneously at the two receivers. The rover receiver may or may not be stationary, depending on the type of the survey operation.

Real Time Kinematic (RTK) surveying is a relative satellite positioning technique, which is especially important technique for mapping and setting out surveys. It offers centimeter accuracies in real time. RTK surveying uses measurements of the phase of the signal′s carrier wave, rather than the information content of the signal, and relies on a single reference station or interpolated virtual station to provide realtime corrections. Satellite positioning is possible when there is line of sight form receiver antenna to the satellites. This means that satellite positioning is not possible in underground mines. In Finland, in open-pit mines, satellite positioning is the main measuring technique. In deep open-pit mines it is possible that satellite availability is too low for measurements. Then total stations are used.

Aerial surveying methods

Aerial surveying refers to various methods of collecting imagery by using airplanes, helicopters, or UAVs. Typical types of data are images on various visible and invisible bands of the electromagnetic spectrum, such as visible, infrared, or microwave bands. Also geophysical data, such as aeromagnetic or gravity data, are collected. Aerial survey should be distinguished from satellite imagery technologies because of its better resolution, quality and different atmospheric conditions.

Photogrammetry is a 3D coordinate measuring technique that employs the use of multiple aerial photos which are triangulated. Working in the same fashion as human eyes do to perceive depth, using multiple photos will derive similar information. A mathematical intersection between two photos can be used to determine 3D measurements. In mining, aerial photogrammetry can be used for example to general mapping and environmental monitoring. Aerial photogrammetry also has the possibility to be implemented into GIS systems for visualization, modelling and analysis purposes.

Airborne laser scanner refers to a remote sensing instrument which uses infrared laser to produce point cloud data of a large area while flying over. Laser scanners are often used in mining to assist with engineering and surveying applications.

The most recent development in aerial surveying is the use of unmanned aerial vehicles (UAVs). They are remotely piloted light aircraft that can carry cameras, laser scanners, and other sensors. Advances in miniaturization, communications, strengths of lightweight materials, and power supplies have permitted significant advances in UAV design. Abbreviation UAV refers usually to the aircraft, only. UAS, unmanned aerial system, is a more comprehensive abbreviation. It includes also the ground control system and pre- and post-processing software. The unmanned aerial systems are highly automatic systems, which has made them easy to operate. Because of this aerial surveying methods have come to everyday use also in Finnish mines.

Conclusions

In Finland, many land surveyors work in public organizations and private companies, which operate in the minerals sector, or which have links to it. Not all of these land surveyors are strictly speaking mine surveyors, but they have certain tasks related to mining.

Mine surveyors are land surveyors who work in demanding working conditions in open-pit and underground mines. They are capable to use highly sophisticated surveying techniques to produce accurately, quickly, and efficiently various 2D and 3D representations of the real ming world in purpose to assist various mining operations. In every Finnish mine you can find a mine surveyor, or even two, or more.

Mine surveyors are especially responsible for maintaining an accurate plan of the mine as a whole. Quite often they are for more than that. As land surveying is a multidisciplinary science, educated and practiced mine surveyors are capable to work in every aspect of a mining operation. Mine surveyors could be a kind of managers of the resources of the mine.

Accurate surveying is based on accurate control points. The maintenance of control network is a very basic task of mine surveyors. In many Finnish mines, control surveys can be seen as a weak point of the present surveying practices. It is quite obvious that standardization of mine surveys, and education related to control surveys, have to be developed in the coming years.

References

Agnico Eagle 2018a. About. 5.3.2018. http:// agnicoeagle.fi/about-us/operation/.

Agnico Eagle 2018b. Media. 27.2.2018. http://agnicoeagle.fi/photos/.

Alatalo, M. 2017. Maanalainen kaivosmitattaus Kittilän kultakaivoksella (Underground Mine Surveying at the Kittilä Gold Mine). Thesis, Lapland University of Applied Sciences, Rovaniemi, Finland, 57 p. In Finnish.

Enemark, S. 2007. Promoting the Interaction between Education, Research and Professional Practice. Scientia Est Potentia – Knowledge Is Power, FIG Commission 2 – Symposium, Czech Technical University, Prague, Czech Republic, 7-9 June, 2007.

Government Degree on Mining Activities 391/2012. The Ministry of Employment and the Economy, Finland. 4.2.2018. http://www.finlex. fi/en/laki/kaannokset/2012/en20120391.

Huhtaniska, J. 2015. Finland’s Minerals Strategy and Education. In: Huhtaniska, J. and Merivirta, M. (eds.). 2015. Mine Your Own Business. Publication series B, Reports 29/2015, Lapland University of Applied Sciences, Finland, pp. 13-18.

Ikonen, L. 2014. Kaivosmittauksen merkitys maanalaisen louhinnan tarkkuudessa (Impact of Mine Surveying on the Accuracy of Undeground Mining). Thesis, Lapland University of Applied Sciences, Rovaniemi, Finland, 44 p. In Finnish.

Kaakkurivaara, T. 2015. Risteysalueiden lisälouhintojen tilavuuksien määrittäminen Kemin kaivoksella (Definig the Volumes of the Underground Intersection Loading Rise Stopings in the Kemi Mine). Thesis, Lapland University of Applied Sciences, Rovaniemi, Finland, 45 p. In Finnish.

KaiVi 2016. Kaivi VR – Siilijärvi Phophate Mine Gameplay. YouTube video. 5.3.2018. https:// www.youtube.com/watch?v=_hXoPOhKhXY.

Laurila, P. 2015. Measuring Technologies in Mine Surveying. In: Huhtaniska, J. and Merivirta, M. (eds.). 2015. Mine Your Own Business. Publication series B, Reports 29/2015, Lapland University of Applied Sciences, Finland, pp. 37-46.

Mining Act 621/2011. Ministry of Employment and the Economy, Finland. 4.2.2018. http://www. finlex.fi/en/laki/kaannokset/2011/en20110621.

Mining Finland. 14.2.2018. http://miningfinland.com/.

The Ministry of Employment and the Economy 2010. Finland’s Minerals Strategy. Geological Survey of Finland. 5.2.2018. http://projects. gtk.fi/minerals_strategy/index.html.

van Wegen, W. 2018. Surveying in the Mining Sector. GIM International. 4.2.2018.

https://www.gim-international.com/content article/surveying-in-the-mining-sector.

This paper was presented at the XXVI FIG Congress 2018 in Istanbul, Turkey, May 6 – 11 2018.

(No Ratings Yet)

(No Ratings Yet)

Leave your response!