| LBS | |

Logistics tracking system based on decentralized IoT and blockchain platform

The paper proposes an approach using a distributed ledger (blockchain) besides a configuable IoT-based system to take into account all needed data including specific case of urban area |

|

|

|

|

|

|

|

|

Abstract

Most of supply chain networks have encountered difficulties when trying to integrate all components and stakeholders (customers, warehouse, transportation, and raw material production), which make supply chain management system suffering from a lack of efficiency and transparency that make a steady increase in good’s falsification and consumer’s disappointment. All information about good’s production, storage and transportation should flow clearly during all stages of the supply chain by tracking and authenticating to avoid product’s contamination or fraud in the network. Current tracking IoT-based systems are built on top of centralized architecture and this leaves a gap for tampering and false information especially in urban area, but also the exsiting solutions cannot allow the information to be shared with authority or consumers. To effectively assess and assure traceability and transparency this paper proposes an approach using a distributed ledger (blockchain) besides a configuable IoT-based system to take into account all needed data including specific case of urban area, with an open data platform at the disposal of stockholders, authority and consumers.

1. Introduction

Over the last decades, supply chain and logistics have greatly grown, rationalized and become a key factor of competitiveness and economic success for almost all companies (industry, commerce, construction, agriculture, services). Supply chain has not only been placed at the center of economists’ attention, but compagnies spend more and more amounts of their turnover on logistics and especially transportation. As the phase of delivery of products and/ or services to final costumers, the supply chain is how nowadays companies turn raw materials into finished goods and services for the clients. In fact, starting with extracting ressources, through refining or manufacturing them into basic parts, assembling those parts into finished products, until selling and distributing finished products to consumer, supply chain is at the center of economic activities. As all companies, logistics ones, have adapted their processes to the dynamics of the moment in order to survive in a very competitive market. In fact, it is not only a question of integrating new technologies, but also great opportunities harness when opting for digitalization as a part of the vision of industry 4.0 [1]. This field is lucky to support a set of technical solutions such as wireless networks, internet of things (IoT), big data, blockchain. The transition from traditional supply chain to a smart supply chain will provide better visibility of the transportation and flexible management. When adopting these new techniques, supply chain can meet market expectations, face new competitors, introduce new links between both companies and partners and thus get more and more benefits. Along with, the wild range of available choices, customers are much more demanding and their satisfaction blended with cost reduction is hard to achieve. Otherwise, supply chain is tending to reach urban customers whose numbers are increasingly significant due to urban migration. Also called “last-mile logistics”, this type has to take into account the congestion, externalities, emissions, space access [2].

This research is considered with the product status during and after the logistics’ chain. For companies’ performance, this status is taken as quality indicator since sensitive or vital products require special treatment and detailed monitoring (vibration, temperature, luminosity, location). On the one hand, the visibility of product status during transportation helps in taking the right decisions in case of an issue. On the other, traceability after chain is over ensuring compliance with specific conditions needed for the product in question. Given all supply chain levels, the information about producing, storing, transporting, and selling goods or services is usually provided by each stage organization. Hence, the reliability of information is compromised. In order to increase their profits, managers of transportation or storage operations may, voluntarily or involuntarily, provide wrong or falsified information. Due to consumer behaviour and supply chain dynamics, logistics network is facing several challenges. K. Wang [1] discussed those challenges and opportunities related to the logistics 4.0 visions and the supply chain digitalization. However, those dynamic changes and adaptations can expose companies and customers to the risk of product damaging. M. M. Aung and Y. S. Chang [3] explained the impact of those risks on the customer’s confidence especially when it comes to food industry which has already experienced problems in the past (food safety scandals, genetically modified foodstuff) P. Olsen and M. Borit [4] defined traceability in the food supply chain as the ability to access to all information also considered as a record and life cycle. N. Egels-Zandén et al. [5] showed the importance of transparency and the difference between transparency and traceability in the supply chain. According to them, there are several tracking solutions such as Bar-coding and RFID combined with localisation sensors based on global positioning system (GPS). H. K. H. Chow et al. [6] presented the integrated logistics information management system. An integration of multiple tracking technologies in a common logistics platform presented as a generic web-based model with a process visualizing using RFID. Also, T. Kelepouris et al. [7] author presented a system using RFID to identify package with GPS and an overloading sensor. A review made by [8] discussed several challenges related to tracking in the urban fright. This study reveals possible interferences that could compromise the quality of the GPS signal especially in urban areas. In the same context, a denser road network due to traffic management can also make tracking more challenging. T. Yokota and D. Tamagawa [9] the author focused on the same issue by applying a map-matching algorithm using dynamic programming to reconstruct the route lengths based on route identification and GPS position data. Recently, the rise of IoT technologies has brought more solutions to these challenges. M. He and J. Shi [10] and many other related papers discussed the implementation of internetof- things technologies in supply chain, with sensors, GPS, wireless connectivity, RFID. K. Sari [11] developed a model to detect the conditions to use RFID technology in supply chain. The model showed an example of the use of RFID technology which has comes with a lot of benefits to the firm especially when it is accompanied by a real collaboration in the chain. Using IoT and RFID, Z. Pang et al. [12] proposed an approach for food supply chain based on a value-centric framework, A. Rejeb et al. [13] discusses the benefit of IoT integration into the logistics networks and also shows examples that this integration is still suffering from inefficiency due to immature in systematic, network, and collaboration perspectives.

Besides IoT technology, blockchain has also drawn much attention in the research field. The first well-known application of blockchain is indeed bitcoin. Since its inception, blockchain has been applied in many domains including supply chain. S. Abeyratne and R. Monfared [14] discussed the benefit of blockchain in the supply chain. They pointed out that the blockchain has not only resolved the lack of trust between stakeholders but also enhanced trust through transparency and traceability within data sharing. In the same context, the distributed/shared database can become more transparent especially in the supply chain network. Also, N. Hackius and M. Petersen [15] pointed on several benefits of using blockchain in the supply chain, such as reducing paper-work, identifying counterfeit products, and tracking the origin of each good. M. Khan et al. [16] discusses the combination of IoT based systems besides blockchain network and their application and benefits to earn people’s trust and transparency in humanitarian logistics. Furthermore, M. Balaji and K. Arshinder [17] presented an open data blockchain based platform capable of long-time open data (BaLOD) that can be validated by anyone. To deal with the above issues, the current contribution presents a transparent approach based on reliable and accessible data collected throughout supply chain phases (transportation and storage). The first section focuses not only on the causes behind falsified/wrong data, but also on challenges facing the supply chain especially in terms of traceability. Furthermore, the second section details the technical architecture of an IoT/ Blockchain-based tracking solution carrying multi-sensors and using RFID/ QR along with an open data service.

2. Research method

2.1. Logistics and traceability

Since the role of the supply chain begins with the purchase of raw materials until the distribution of finished products, the full product transportation lifespan differs depending on the number of intermediaries in the supply chain. The more intermediaries the chain has, the greater the risk of losing product quality will be, along with carbon emissions due to transportation [2], delay of payments and high transaction waiting time [18]. When the contract is signed, consumers oblige companies to justify time, place, and causes of any issues. If the latter happens, companies can receive sanctions, betray the trust of their partners, lose market share and even harm their own development. Hence the necessity to adopt traceability systems in order to minimize risks for clients and ensure at best, at worst, verification of quality and safety of goods supplied [3].

Product traceability solutions come with many benefits to businesses by helping them identify critical points in the supply chain, resolve incidents without delay, gain productivity, and provide to the company a solution for the shortage of data about product manufacture and raw materials used [14]. Indeed, companies can handle the quality reduction of the contamination of goods and increase the quality of the service they offer to their consumers. On the other hand, the solutions allow consumers to improve the level of their confidence when purchasing a product or service. An appropriate solution must encompass all features of a supply chain, transits made in different countries is also included. This is the reason why the actors in the supply chain are obliged to share the same data structure and that the products are referenced using identification for external use.

One critical element goes along with traceability is transparency. Unlike traceability that conveys granular and batch-lot data and even unverified and falsified claims, transparency refers to receiving and transfering high-level information related to the product and suppliers from and to stakeholders [5] (certifications, expiration date, location of facilities,) without a risk of loss or distortion [19]. Supply chain planning systems allow the analysis of resource capacity and constraints in order to suggest the right path to optimal production.

There are several types of product traceability such as tracking, which means the possibility of holding the data of routes travelled by a load unit or a batch of goods using unique IDs or recorded identifications such as RFID [20]. It helps to know the routing path of a product and to better calculate delivery times. Tracking is the most used type of traceability for on-line shopping. It allows us to know all the stages done by a product until its final destination. To make sure all stages of supply chain are carried out under the best possible conditions, geographic coordinates provided by a GPS are not the only information needed. Traceability can be extended to cover other parameters as well. For example, special products such as drugs, blood units, chemical products, and also food, need to be protected from degradation in each stage of the supply chain, especially from temperature, light and humidity [21].

In recent years, the amount of urban population has increased along with the demand for goods and products. Thus, the home delivery services return goods and supplied products has considerably expanded and created tense flow management and contributed to the increase of number of truck traffic in cities. This type of transportation depends on several aspects and has required much attention. In fact, urban freight is more questionable in terms of traceability and transparency due to short trips, complex roads, stops and congestions that enhance fuel consumption up to 140% [22], delay transportation and increase transportation’s budget. Also, the weakness of GPS signals due to tall buildings and narrower streets in urban environments [8]. In this case and to monitor those aspects, the GPS data, temperature and vibration can be considered as an exposure due to several natures of supplied products. For example, the last two are important parameters for tracking products like frozen food, drugs, blood, and vaccines [23].

2.2. Traceability via blockchain and IoT

Internet of things the proposed tracking system relies on the combination of several instruments. The main technology to consider is Internet of Things. Theses devices, mass-produced and utilised in industry since 2012, provide new ways to approach well-known challenges of the supply chain, the most important of which is collecting real-time data. Like in many other systems [24], IoT is here integrated as a connected mean of tracking products with the purpose of renewing customers’ confidence in products [25].

Also, this system is equipped with radio frequency identification (RFID). Along with IoT, RFID helps to identify packages by using electromagnetic fields to identify tags attached to any package which contains stored data. This type of identification is more effective for parts that use pallets, trucks, forklifts or boxes level storage and delivery. However, it will be less useful for the final consumer, especially if the packages contain several products to be dispatched to other final consumers item by item. In this case, an additional linked identifier is needed in every product and not the whole package.

Researchers, industrials and managers have taken a very strong interest in the use of IoT technologies together with RFID for package identification and QRcode for product identification. Due to its faster readability using a camera or personal digital assistant (PDA), larger storage capacity as identifiers and reasonable expenses, QRcode becomes more and more approved and popular with the supply chain [26].

Technically, by reading tag/code, the RFID and QRCode identify the package and the product. RFID and QRCode can be separated from the IoT architecture. However, the current architecture merges those identifiers with IoT sensing devices to make data more centralized. Based on urban freight specific needs as discussed in the previous section, temperature sensors, vibration detector, and GPS chip can be added to the IoT devices to collect environment data and send it to a third part service via a gateway. The system requirement needs to allow the functionality to meet the customer needs and maintenance costs.

• Quality evaluation & environment change control. The system collects environment changes from a group of sensors linked to the IoT device that can even monitor temperature and vibration, and GPS to evaluate the quality and safety of the products.

• Wireless communication. The device exchanges data with a gateway via wireless communication

• The device sends time/sensor information (including unusual events) for a gateway.

• Information services. The data needs to be presented to any player in the chain via services to be used for strategic purposes or to track down the sources and the storage and delivery conditions.

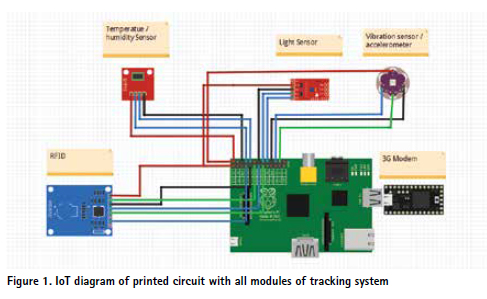

As proposed in Figure 1 the architecture is based on temperature, humidity, light, and vibration sensors and GPS. This device records parameters and details about the transported packages at real-time.

The device is planned to be in a box inside the transport compartment as close as possible to the transported package, the device will have the following components:

• Raspberry Pi 4 Model B: a small single-board computer, uses a 1.5 GHz 64-bit quad-core ARM Cortex-A72 processor and enough connection ports to support sensors.

• Temperature Sensor: records temperature in the form of resistance value using a thermistor. The Arduino Uno converts the measured voltage by the input pin to the real value of temperature in °C. The measurement is expected to vary between -40 to 125 °C with an approximated error of 1.5 °C.

• Light Sensor: This sensor uses a lightdependent photo-resistor that detects light and which resistance decreases when light intensity increases.

• Humidity Sensor: The humidity sensor uses capacities measurement to determine the amount of moisture in the air.

• Vibration Sensor: To detect vibration, the device uses an Accelerometer. Also, a piezoelectric sensor could be adopted for more accuracy.

• 3G modem: Ensure connectivity to the server to get the configuration and send the data.

• RFID: RFID RC522 tag writer and RFID TAG.

In the proposed architecture, each transport vehicle or package will have a pre-installed box to monitor various metrics highlighted by the logistics service agreement between various players.

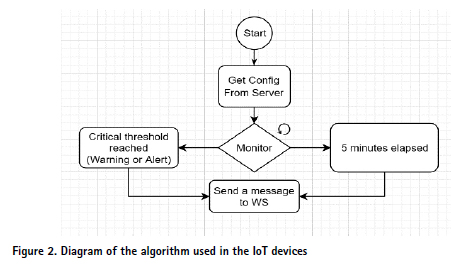

The critical values for these metrics change depending on the transported goods. For example, for tracking fish transportation, the temperature is crucial, but not vibration. Also, for drug transportation, the vibration and the temperature both are crucial. Those configurations are selected and highlighted by the logistics service agreement. For urban areas and rural areas, this configuration can have a time interval. It can have additional cases such as time intervals for ocean freight or air freight. Once a vehicle is assigned to carry a package, the Raspberry Pi should be configured appropriately. The configuration sets the identifier in the RFID tag and runs the sensor. The Raspberry Pi is then programmed to perform the Figure 2 algorithm.

The device is programmed to get the current thresholds for warnings and alerts from the server while monitoring all sensors and sends their data to the server based on a time interval (urban and/or rural areas). When a sensor’s value exceeds the configured threshold, a message (with all sensing data) is sent to the server with the corresponding gravity (info, warning, or alert). In case of weak/ missed mobile network connectivity, IoT data collected are stored locally to be sent once the device connected.

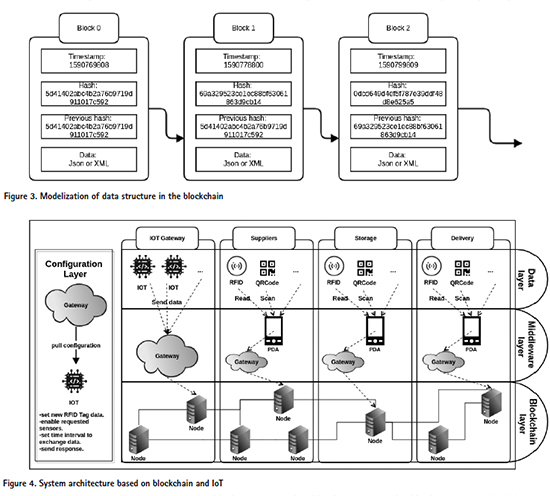

Blockchain service is a transparent and secure information storage and transmission technology. The first blockchain appeared in 2008 with the advent of digital currency “bitcoin”, developed by a nameless programmer known as Satoshi Nakamoto. Blockchain operates without a central control unit, allowing each of its users to check the validity of all information including new ones. Exchanges are recorded and grouped at regular intervals in transaction blocks which are linked together and form unique and tamper-proof chains of information. It consists of a database shared by its different users, which contains the history of all the exchanges made between these users since its creation. The data in each block is protected and cannot, therefore, be modified or altered after each fact, unless the whole network agrees. The ledger is made up of a set of blocks. Each block contains two parts. The first part represents the body of the block and contains the transactions that the database must record. The nature of the transactions can be any useful data, it can be monetary transactions, medical data, industrial information, system logs,. The second part is the block header. It contains information concerning the block such as the timestamp, the transaction hash,. As well as the hash of the previous block. As a result, all the existing blocks form a chain of linked and ordered blocks. The longer the chain is, the more difficult the falsification can happen. If a malicious user wants to modify or exchange a transaction on a block, he must modify all the following blocks, since they are linked by their hashes. But also, it must change the version of the blockchain that each participating object stores. Figure 3 illustrates a simplified example of a blockchain.

To prove the honest validation of a block, there are many validation mechanisms. The most used are the proof of work (PoW) mechanism and the proof of stake (PoS) mechanism. Also, when the validator of a new block needs to be a real entity in the system. proof of authority (PoA). proof of elapsed time (PoET) can be used for reducing time and resource consumption [27].

Recently, several agriculture, fresh food applications and researches, use Blockchain in order to ensure data trust and data immutability. In every system that carries Blockchain, it guarantees interaction with all players (by role) and authorization, and reduces costs of creation inspection for specific accidents like food contamination for example [28]. When Blockchain is used in logistics, it helps to track the product origin, identify products who may be contaminated, and decrease the paperwork process [15]. Blockchain applications can also be used for product traceability by providing product history for suppliers and retailers. In this way, the origin and the quality of the product can be verified [29]. As mentioned before, unverified claims, deliberate fraud, or false data are, among others, issues in the logistics industry especially when it comes to information safety. Thus, to prevent any kind of change in data, a blockchain can assure the data integrity. The proposed module is a multicriteria traceability architecture based on blockchain and IOT. It consists of 5 layers.

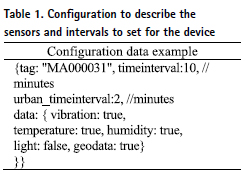

Configuration layer: It refers to corresponding IoT devices. With the IoT Gateway sending data. This layer provides information about which sensors to be enabled and also to set RFID data for the device. The IoT Gateway on the other hand can keep a heartbeat token related to the device (with a keep-alive interval and different time interval between the urban area and rural area to detect if there is any sort of connection loss, specifically out of coverage area. Table 1 resume a sample of data sent to the IoT sensor.

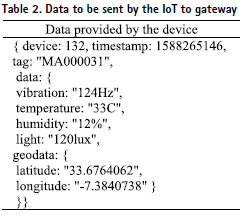

Data layer: This part provides the data to share with other parties. The RFID and the QR code are used for physical examination. They give a tag that identifies the package. However, the data provided with IoT devices are more complex. It consists of measurements and units for each sensor. Table 2 present a sample of the json data receive from the Iot to the gateway with the details captured by the sensors.

Middleware layer: to collect events and change the status of the package, the system needs to be able to interact with the previous layer. Each player in the system can visualize package history or using a PDA or RFID/QR code scanner. Once the scan is completed, the data is sent to the internal gateway. The IoT gateway also receives the data from the devices with the collected/ cached data. This data can be formatted, organized, or cleaned by the gateway.

Blockchain layer: To have a distributed database that can store all status for a package during all stages, it surely needs to be available for each player in the system. This layer ensures a peerto- peer connection between each node of the network to exchange data. The supplier, storage and delivery nodes can only change the status of the package (by adding a new block to the chain referencing the package tag) in order to identify transactions status (in transit/ pick up/undelivered/delivered/expired). Without changing any sensing data, the blockchain can manage data by using proof of authority (PoA) algorithm for validation in the network. On the other hand, the IoT Gateway node is the only node that can add sensing data to the blockchain network using the data received from devices through the gateway. The gateway can set or change the status of the package in the system (Info, Alert, Warning, and Not Connected). The Figure 4 explains the integration ond communication with differents componenets and layer in the proposed approach.

The IoT devices receives configuration via the gateway as first, the configuration as showen previously, can have several information about what sensors the enable and the specification for urban area. The device can be connected to a gateway in a midlware stage, it can also have a PDA as an input into the gateway besides the IoT devices. In this layer in the propsed approach the main goal is to prepare, filter data, and make an input node to the blockchain network.

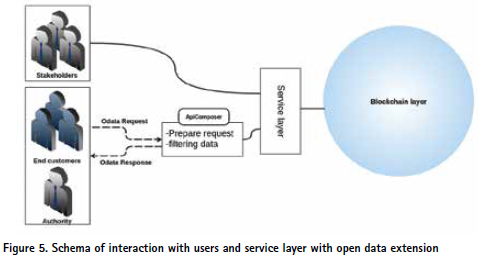

Services layer: stakeholders or players need to be notified of any change to make management decisions, statistics and creating a dashboard. However, to perform any of management actions, the data in the blockchain layer needs to be available via services. It is that service which identifies the product and each data related to it. Also, there are other collaborators such as the final customer and authority party who need to have custom access to the network data (transit status, product quality, GPS location), via services such as open data [17], or web services. Figure 5 describe the interaction of the service layer with open data platform. The goal is to make a suitable response to each collaborator, with the concerned information and to assure an integrity and security for the information. Whatever nature the data to be shared, the open data will control the authority of the request before filtering and prepare the response.

3. Comparison and results

Since the advent of Internet of Things in 1999 [30], many applications have been proposed, notably in smart logistics. IoT applications in supply chain management, as suggested in the literature review, the utilization of IoT along with both RFID/ QR and Blockchain has not been examined in substance. However, most blockchainenabled solutions, even significant, are limited in scope and applicability. In [1] the author presented the evolution process of logistics and made emphasis on the fourth innovation of logistics being Internet of Thing and Service. Along with Mechanization first, Automation second and management third, the last generation of logistics relay on many technologies and technical components such as Automatic Identification, Real-time Location, Smart Sensing, Networking, Data analying and Internet of business service. This study underlines two cases of Logistics 4.0. The first, related to the function of identification, describes the intelligent and integrated RFID (IIRFID) System architecture (assest level, data acquisition level, control level, database level, decision support level and management level). Whereas, the second consists on a a real time location system.

Compared with these solutions, the logistics tracking system, as previously introduced, is a pure and simple logistics 4.0 platforms with enhanced security. In fact, by adopting a blockchain layer along with RFID technology, the tracking system increases the security aspect of the device and the integrity of collected data. The blockchain allows uniquely the addition of new approved blocks to the chain, constitutes a distributed and inviolable database with all packages’ status and ensures peer-to-peer connection in order to exchange data. However, regarding the second application of the same study, the Real Time Location System introduces by K.Wong [1] consists of building production workshop or other area in order to automatically identify and track objects or people. This workshop uses Wireless RFID tags attached to objects or worm by people and fixed to reference points. Instead, Logistics tracking system based on decentralized IoT/blockchain platform includes GPS chip capable of determination of geographic coordinate and precise location with queuing system in critical cases (weak GPS signal and weak 3G). Also this system takes into consideration urban specifications and gives possibility to adjust frequency of data collecting and transfer depending on ongoing environment. This project is not only an intelligent and integrated with RFID, but a secured one as well.

Another project to consider is the Chinese Ministry of science and internet of things solution for food safety and quality control [24]. This project initiates internet of agricultural things (AIoT) which architecture is composed of data access and transmission layers, application service platform, application module layer and User application. AIot project lunched since 2011 over six Chinese universities and institues after several serious food safety incidents provides a method to easily track and trace food supply chain. By combining both global identification and parsing along with electronic pedigree, this project helps users and consumers to evaluate food quality. Once again the integrity of collected data can be compromised given its stakes, hence the need of blockchain implementation. Also the last project appears to be dedicated only to agricultural products and needs to be expanded to all types of supply chains.

Last but not least, H. Tran-Dang et al. [31] has modelled food supply chain (FSC) traceability using blockchain technology and smart contracts. The use of blockchain is justified to overcome obstacles to traditional FSC traceability mechanisms, such as lack of security, information sharing, and systems integration difficulties. Furthermore, in order to increase visibility and interaction with all actors of the supply chain, this architecture could have integrated an open data solution. In fact, as presented before, in order to make management decisions, statistics and dashboards, stakeholders need to access to all data at any time and place. Also, authorities and consumers need to know product details and supply chain conditions to check the conformity to requirements and decide whether to purchase it or not.

Compared to the above solutions, our Logistics tracking system based on decentralized IoT/blockchain platform differs in the following aspects:

• The current solution is a blockchain based platform for more security and integrity of data

• This platform consists of on RFID or QRCode rapid authentification

• Is consists of a hybrid modelling with a large applicability to almost all types of chains

• This model takes into account urban environment with specific requirements

• an open solution available for all players since it implements an open data

4. Conclusion

Real-time and multi-criteria tracking are important not only to make supply chain management more effective but also to ensure package safety and quality. This paper has proposed a decentralized IOT/blockchain-based platform with multi-sensors and RFID & QRcode technologies to simplify the interaction between stakeholders and packages while in transit. Data relative to temperature, light, humidity, vibration, and geo-position is the main data to be exchanged in the platform. However, the platform can be extended to carry other data by adding new sensors to IoT devices such as weight sensors for fragile packages. An open data API is proposed as well to give to the end customer access to the history of the product using the QRcode. This platform can be used by any type of logistics such as hospitals and cold logistics to prevent falsified and wrong data. It can help improve the quality of service and detect damaged products. The current model can be improved by ensuring a better identification between the IoT devices and the IoT-gateway. The validation in the blockchain layer can be changed based on the need or the product type. Also, securing the communication between the IoT and changing the communication protocol can be a subject to improve, besides merging the node to a cloud solution. However, the same architecture can be remaining. Some limitations of the proposed traceability model should be kept in mind such as the possible lack of network coverage particularly with long supply chains (in air planes and ships) This limitation must delay the data transfer until the network is restored. Also, blockchain is not suitable for storage of vast amount of data and most Blockchain based models suffer from lack of scalability. In addition, each components inherent some limitations, such as IoT reliability on battery or other power source.

References

[1] K. Wang, “Logistics 4.0 Solution- New Challenges and Opportunities,” in 6th International Workshop of Advanced Manufacturing and Automation, 2016, pp. 68-74, doi: 10.2991/iwama-16.2016.13.

[2] F. Yu, L. Xue, C. Sun, and C. Zhang, “Product transportation distance based supplier selection in sustainable supply chain network,” Journal of cleaner production, vol. 137, no. C, pp. 29-39, 2016, doi: 10.1016/j.jclepro.2016.07.046.

[3] M. M. Aung and Y. S. Chang, “Traceability in a food supply chain: Safety and quality perspectives,” Food Control, vol. 39, pp. 172-184, 2014, doi: 10.1016/j.foodcont.2013.11.007.

[4] P. Olsen and M. Borit, “How to define traceability,” Trends in food science & technology, vol. 29, no. 2, pp. 142-150, 2013, doi: 10.1016/j.tifs.2012.10.003.

[5] N. Egels-Zandén, K. Hulthén, and G. Wulff, “Trade-offs in supply chain transparency: The case of Nudie Jeans Co,” Journal of Cleaner Production, vol. 107, pp. 95-104, 2015, doi: 10.1016/j.jclepro.2014.04.074.

[6] H. K. H. Chow, K. L. Choy, W. B. Lee, and F. T. S. Chan, “Integration of web-based and RFID technology in visualizing logistics operations – A case study,” Supply Chain Management, vol. 12, no. 3, pp. 221-234, 2007, doi: 10.1108/13598540710742536.

[7] T. Kelepouris, K. Pramatari, and G. Doukidis, “RFID-Enabled Traceability in the Food Supply Chain,” Ind. Manag. Data Syst., vol. 107, pp. 183–200, Mar. 2007, doi: 10.1108/02635570710723804.

[8] J. Gonzalez-Feliu, P. Pluvinet, M. Serouge, and M. Gardrat, “GPSbased data production in urban freight distribution,” Global Positioning Systems: Signal Structure, Applications and Sources of Error and Biases, pp. 1-20, 2013.

[9] T. Yokota and D. Tamagawa, “Route Identification of Freight Vehicle’s Tour Using GPS Probe Data and its Application to Evaluation of on and off Ramp Usage of Expressways,” Procedia – Social and Behavioral Sciences, vol. 39, pp. 255-266, 2012, doi: 10.1016/j.sbspro.2012.03.106.

[10] M. He and J. Shi, “Circulation traceability system of Chinese herbal medicine supply chain based on internet of things agricultural sensor,” Sustainable Computing: Informatics and Systems, vol. 30, p. 100518, 2021, doi: 10.1016/j. suscom.2021.100518.

[11] K. Sari, “Exploring the impacts of radio frequency identification (RFID) technology on supply chain performance,” European Journal of Operational Research, vol. 207, no. 1, pp. 174-183, 2010, doi: 10.1016/j.ejor.2010.04.003.

[12] Z. Pang, Q. Chen, W. Han, and L. Zheng, “Value-centric design of the internet-of-things solution for food supply chain: Value creation, sensor portfolio and information fusion,” Information Systems Frontiers, vol. 17, no. 2, pp. 289-319, 2015, doi: 10.1007/s10796-012-9374-9.

[13] A. Rejeb, S. Simske, K. Rejeb, H. Treiblmaier, and S. Zailani, “Internet of Things research in supply chain management and logistics: A bibliometric analysis,” Internet of Things, vol. 12, p. 100318, 2020, doi: 10.1016/j.iot.2020.100318.

[14] S. Abeyratne and R. Monfared, “Blockchain Ready Manufacturing Supply Chain Using Distributed Ledger,” International Journal of Research in Engineering and Technology, vol. 5, no. 9, pp. 1-10, 2016.

[15] N. Hackius and M. Petersen, “Blockchain in Logistics and Supply Chain: Trick or Treat?,” in Digitalization in Supply Chain Management and Logistics: Smart and Digital Solutions for an Industry 4.0 Environment. Proceedings of the Hamburg International Conference of Logistics (HICL), 2017, vol. 23, pp. 3-18, doi: 10.15480/882.1444.

[16] M. Khan, S. Imtiaz, G. S. Parvaiz, A. Hussain and J. Bae, “Integration of Internet-of-Things With Blockchain Technology to Enhance Humanitarian Logistics Performance,” in IEEE Access, vol. 9, pp. 25422-25436, 2021, doi: 10.1109/ACCESS.2021.3054771.

[17] M. Balaji and K. Arshinder, “Modeling the causes of food wastage in Indian perishable food supply chain,” Resources, Conservation and Recycling, vol. 114, pp. 153-167, 2016, doi: 10.1016/j.resconrec.2016.07.016.

[18] G. J. Hofstede, L. Spaans, H. Schepers, J. H. Trienekens, and A. J. M. Beulens, “Hide or confide: the dilemma of transparency,” Reed Business Information , Netherlands , 2004.

[19] W. He, E. L. Tan, E. W. Lee and T. Y. Li, “A solution for integrated track and trace in supply chain based on RFID & GPS,” 2009 IEEE Conference on Emerging Technologies & Factory Automation, 2009, pp. 1-6, doi: 10.1109/ETFA.2009.5347146.

[20] R. H. Bishara, “Cold chain management – An essential component of the global pharmaceutical supply chain,” American Pharmaceutical Review, vol. 9, no. 1, pp. 105-109, Jan. 2006.

[21] Martensson, “Volvo’s environmental stratgey for next generation trucks,” Environmental Affairs, BESTUFS Conference Volovo Truck Corporation, vol. 1, 2005.

[22] B. Yan and D. Lee, “Application of RFID in cold chain temperature monitoring system,” 2009 ISECS Int. Colloquium on Computing, Communication, Control, and Management, 2009, pp. 258-261, doi: 10.1109/CCCM.2009.5270408.

[23] J. H. Trienekens, J. G. A. J. van der Vorst, and C. N. Verdouw, “Global Food Supply Chains,” BT-Encyclopedia of Agriculture and Food Systems, 2nd edition, pp. 499-517, 2014, doi: 10.1016/ B978-0-444-52512-3.00118-2.

[24] Y. Liu, W. Han, Y. Zhang, L. Li, J. Wang, and L. Zheng, “An Internet-of-Things solution for food safety and quality control: A pilot project in China,” J. of Industrial Information Integration, vol. 3, pp. 1-7, 2016, doi: 10.1016/j.jii.2016.06.001.

[25] S. Qiao, Z. Wei, and Y. Yang, “Research on Vegetable Supply Chain Traceability Model Based on Two-Dimensional Barcode,” 2013 Sixth International Symposium on Computational Intelligence and Design, 2013, pp. 317-320, doi: 10.1109/ISCID.2013.86.

[26] M. Salimitari and M. Chatterjee, “A Survey on Consensus Protocols in Blockchain for IoT Networks,” arXiv preprint arXiv:1809.05613, 2018.

[27] K. Leng, Y. Bi, L. Jing, H.-C. Fu, and I. Van Nieuwenhuyse, “Research on agricultural supply chain system with double chain architecture based on blockchain technology,” Future Generation Computer Systems, vol. 86, pp. 641-649, 2018, doi: 10.1016/j.future.2018.04.061.

[28] Q. Lu and X. Xu, “Adaptable Blockchain-Based Systems: A Case Study for Product Traceability,” in IEEE Software, vol. 34, no. 6, pp. 21-27, November/December 2017, doi: 10.1109/MS.2017.4121227.

[29] O. Vermesan and P. Friess, Internet of things: global technological and societal trends, Denmark: River Publishers, 2011.

[30] F. Casino, V. Kanakaris, T. K. Dasaklis, S. Moschuris, and N. P. Rachaniotis, “Modeling food supply chain traceability based on blockchain technology,” IFAC-PapersOnLine, vol. 52, no. 13, pp. 2728–2733, 2019, doi: 10.1016/j.ifacol.2019.11.620.

[31] H. Tran-Dang, N. Krommenacker, P. Charpentier, and D.-S. Kim, “The Internet of Things for Logistics: Perspectives, Application Review, and Challenges,” IETE Technical Review, pp. 1-29, 2020, doi: 10.1080/02564602.2020.1827308.

The article, first published in Indonesian Journal of Electrical Engineering and Computer Science, Vol. 23, No. 1, July 2021, pp. 421~430, ISSN: 2502-4752, DOI: 10.11591/ ijeecs.v23.i1.pp421-430, is republished with authors’ consent.

This is an open access article under the CC BY-SA license.

(3 votes, average: 1.00 out of 5)

(3 votes, average: 1.00 out of 5)

Leave your response!