The signature attribute of the crawl-walk- run methodology is the controlled, repeatable environment in which proper functionality of the unit is analyzed. With physical and functional checkouts, the navigation unit is rechecked as necessary to methodically verify the test item's performance. Further, the crawl-walk-run methodology works to gradually increase the dynamics and signal stress on the test item as the program continues. This gradually escalating strain on the GINS' sensors is designed to bring the system to its specification limits and expose issues while measuring performance.

The 746 TS utilized many of its available resources to conduct this significant test program. The testing was primarily conducted at the 746 TS complex and nearby White Sands Missile Range (WSMR) using the organization's state-of- the-art Truth Reference System, the CIGTF Reference System (CRS).

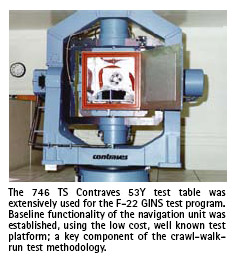

The test program began in June 2008 in the 746 TS' flight dynamics lab to establish baseline performance measures for the F-22 GINS unit. The Contraves 53Y precision 3-axis test table was used to perform bench top physical and functional checks of the GINS. Inexpensive and highly repeatable table testing is the core component of the test methodology and provided baseline data for the test team in their analysis of the GINS unit.

The GINS unit was sequentially rotated to 25 positions on the 53Y table and aligned to the table's inner axis within ±3 arcmin, according to the GINS manufacturer's specifications. The INS system was tested to 18 deg/sec rotation rates. The GINS completed several Gyrocompass (GC) Alignment, Stored Heading (SH) and Calibration Evaluation tests. The 53Y test table was utilized several other times in the test program to easily and economically identify and troubleshoot performance issues with the unit.

During this baseline lab testing, a GINS performance issue was uncovered. A standard calibration evaluation test revealed the inertial heading and roll errors were out of spec when the GINS was pitched at 90 degrees up or down. Upon further research, the 746 TS discovered that the blended attitude demonstrated similar behavior. The problem was reported to the 746 TS customer, who was able to respond to the problem by implementing corrections before further testing was conducted, thus saving the program considerable time, effort, and flight costs. If the test item had been put directly into the higher dynamic flight testing phase, this issue would have been uncovered at a substantially higher cost and with great delay to the program schedule. By catching the issue early in lab testing, $15,000 of flight testing costs, $9,000 of analysis troubleshooting costs and weeks of delays were avoided.

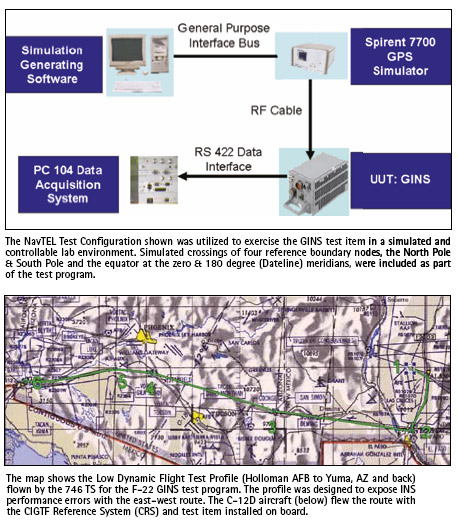

The next step in the crawl methodology for the GINS test program was to move into the Navigation Test & Evaluation Laboratory (NavTEL). NavTEL is the 746 TS modeling and simulation lab capability offering hardware in the loop testing designed to effectively and efficiently stress EGI systems under test. This laboratory provides a Radio Frequency (RF) sterile laboratory environment with the capability to replicate real world operations in a controlled, scientific manner. The Satellite Tool Kit was used to predict and analyze GPS denied operational effects on the GINS. After it passed the tests, the team confidently moved into the walk phase of the test program.

The program progressed to low dynamic ground testing with the controlled environment and medium cost that is characteristic of the walk methodology. Dynamic ground test and low dynamic flight test beds were used for several months of operationally realistic test missions with the GINS and CRS on board. The CRS provides sub-meter accuracy in low-to-high dynamic environments, is capable in clean air and GPS denied environments and is extremely mobile and versatile because it can be palletized and utilized for van and flight testing.

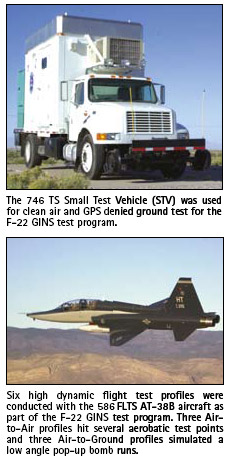

Dynamic ground testing on the GINS program schedule started on the Small Test Vehicle (STV). The STV is a very versatile asset for navigation testing. It can be modified for a vast array of antenna configurations including up to three Controlled Reception Pattern Antennas (CRPA) and Fixed Reception Pattern Antennas (FRPA). It has onboard power for the test item and can carry up to three pallets and three operators.

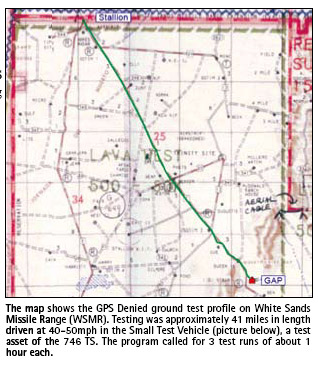

The test team leveraged the capabilities of the STV in three, 2-hour clean air test profiles conducted on WSMR. The 60-mile roundtrip route conducted at 40-50 mph began and ended at CIGTF with a turnabout at the Small Missile Range on WSMR. Next, a GPS-denied environment was created using the 746 TS portable box jammer. A static ground jamming test was conducted at the Static Antenna Test Range, part of the CIGTF complex. The GINS and CRS endured a 2 dB/min jammer ramping scenario inside the parked STV.

The 746 TS conducted several one-hour GPS denied dynamic ground profiles on WSMR where the GINS was again subjected to ramping jamming scenarios. The 41 mile route went from the WSMR Stallion site to Gap site and back to Stallion at a speed of approximately 40-50mph.

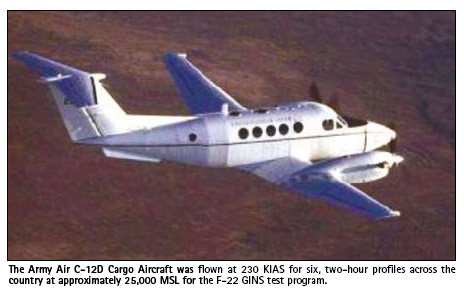

Low dynamic flight testing was next on the GINS test schedule. East to west profiles were flown in an C-12D cargo aircraft in a profile designed to expose INS performance errors. The C-12D is operated by the Army Air Directorate at Holloman AFB. Six profiles with two-hours of flight data per profile were conducted from Holloman AFB to Yuma, AZ. The two-hour profiles included gyro compass align, inflight alignment and INS-only testing at 230 KIAS. At this time, a new Operational Flight Plan (OFP) was installed on the GINS unit by the manufacturer. Per 746 TS test methodology, the unit was removed from the C-12D aircraft and rechecked for functionality and baseline performance before flight testing was resumed. Regression checkouts were completed on the GINS utilizing 746 TS lab capabilities prior to re-testing on the C-12. The low dynamic 53Y lab testing was repeated to ensure the GINS still functioned properly. Key errors in the OFP upload were identified that would have otherwise been found during flight testing. The upload was re-accomplished and the GINS was found to be functioning properly. The test team avoided $10,000 in C-12D flight testing and $6,000 of analysis troubleshooting costs by catching this problem in the lab.